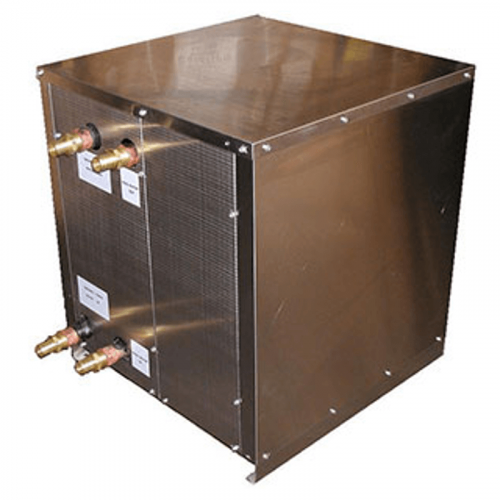

Our larger, dual-circuit 10-20 Ton process chiller line are an excellent budget-friendly choice for applications requiring a modular, scalable design. These units are also frequently used to replace antiquated chillers where existing buffer tank and distribution components are still operational and the customer prefers to simply replace the chiller portion. This new process chiller module can simply be added to the existing tank system to augment or replace the existing chiller capacity.

These dual-circuit process chillers are available from 10-20 Ton. The secondary circuit can provide the performance advantages of a two-stage system, and/or serve as back-up capacity for the primary circuit.

Evaporator

Because these chillers have no built-in reservoir, either a brazed-plate [standard] or tube and shell [option] heat exchanger is used for the evaporator. These models do not come with our "no-freeze" evaporator.

Electrical

We use nothing but ETL & UL approved components. These larger process chiller designs can be built for: 208/230V 3-Phase, 460V 3-Phase, and 575V 3-Phase. Each process chiller includes built-in temperature control which utilizes the very dependable and versatile RANCO controller. Please inquire if you need something more custom or have questions about any of the listed features and upgrade options.

Refrigeration

ChillX Chillers are built using only the best refrigeration circuit components -- no expense has been spared to ensure many years of efficient, and dependable service. Our standard chiller designs use readily available off-the-shelf components, for easier maintenance and serviceability.

Features

- Direct drive fan motors

- High-capacity driers

- High-pressure switch

- Loss of charge switch

- Exterior refrigerant service valves

- Low ambient start to 0F

- Heavy gauge pre-painted steel cabinet

- Built-in two-stage thermostatic control

- Warranty: 5 year limited compressor, 1 year limited for remaining covered parts

Options / Upgrades

- Low Temp upgrade (25-28F LWT)

- Hot Gas Recovery: Secondary condensor to capture otherwise rejected heat, commonly used to augment de-humidification applications.

- Tube & shell heat exchangers options available for augmented freeze protection

- Heat pump upgrade

- Hail guards

- Controller cord extension upgrade

Installation Notes

Please note, process chiller designs do not include a built-in reservoir or circulation pump. So, depending on your situation, you may need to acquire and install a buffer tank and distribution system. This most commonly includes: (1) buffer tank, (1) dedicated chiller circulation pump, (1) process circulation pump, and some sort of chilled water distribution manifold and controller system. We're happy to help advise on those components regardless if we supply them, please just let us know if we might help.